Singapore’s manufacturing base is compact but powerful. Electronics, precision engineering, biopharmaceuticals, and aerospace together deliver roughly a fifth of national output.

These sectors now rely on connected data as much as machines. Integration Platform as a Service (iPaaS) helps factories move beyond custom scripts and spreadsheets toward managed workflows that support Industry 4.0 and Smart Nation ambitions.

Integration Challenges in Singapore’s Manufacturing Sector

Singapore offers strong infrastructure, talent, and policy support. The harder problem for manufacturers is making diverse systems, plants, and partners behave like one operation.

Complex Multi-Site, Multi-System Environments

Many manufacturers run regional headquarters in Singapore while operating plants across Asia. ERP sits in one place, plant systems in another, and partner platforms outside the corporate network.

Sales teams work through distributors and contract manufacturers. Engineering uses specialised design and quality tools. Logistics partners bring their own portals and tracking systems.

Without a shared integration layer, each new partner or plant connection becomes a separate project. Over time, the mesh of custom integrations becomes difficult to upgrade, monitor, and secure.

Compliance, PDPA, And Cloud Adoption

Singapore’s Personal Data Protection Act (PDPA) sets clear expectations for how organisations collect, use, and protect personal data. Guidance from the regulator also addresses secure use of cloud platforms and data intermediaries.

Manufacturers that handle employee data, customer information, and supplier details must balance those requirements with the desire to adopt cloud services. Plant teams often prefer on-premise deployments, while commercial and finance teams favour Software as a Service.

Connecting all of this safely is challenging. Each point-to-point integration needs security reviews, audit trails, and contingency plans, which slows down projects.

Talent Constraints And Manual Workarounds

Integration specialists are limited, especially engineers who understand both OT and IT. When those teams are busy, departments fall back to manual work.

- Email Attachments: Orders and forecasts travel as spreadsheets and PDF files.

- Shadow Tools: Individual teams track quality, scrap, or downtime in local applications that never sync back.

- Copy-Paste Integration: Staff retype data between portals, ERP screens, and reporting tools.

These workarounds keep lines running but introduce errors and delay decisions. The more Singapore manufacturers push into advanced manufacturing, the more this gap becomes visible.

Why iPaaS Is Driving Smart Manufacturing in Singapore

Singapore’s manufacturing agenda is explicit: higher value, smarter factories, and data-led decisions. iPaaS has emerged as a practical enabler inside that agenda.

Alignment With Smart Nation And Industry 4.0 Programs

Government agencies encourage Industry 4.0 through incentives, training, and structured frameworks. One well-known example is the Smart Industry Readiness Index, which helps plants assess their current state and plan transformation.

Almost every roadmap under that framework needs reliable data flows: from machines to MES, from MES to ERP, and from ERP to partners. iPaaS gives teams a way to coordinate these flows without rebuilding core systems.

Instead of treating integration as a collection of scripts, companies treat it as a program: model domains, set standards, and track performance.

Support For Hybrid And Multi-Cloud Strategies

Singapore manufacturers are adopting hybrid cloud architectures to balance agility and control. ERP may run in a private cloud or local data centre. Analytical platforms, customer portals, and collaboration tools often sit in public clouds.

iPaaS platforms support this topology directly. They connect on-premise systems through secure agents while orchestrating flows in the cloud. Data moves according to policy, not convenience.

This matters for plants that want to keep production data close to the line while still feeding central analytics and planning models based in the cloud.

Regional And Global Integration Requirements

Many manufacturers in Singapore act as regional hubs. They coordinate supply chains that stretch across ASEAN, North Asia, and beyond.

iPaaS helps these companies treat integration as a repeatable capability. Once a standard pattern for “new logistics partner” or “new contract manufacturer” exists, teams reuse it in other markets.

At the same time, the wider Asia–Pacific iPaaS market is expanding steadily, as more organisations adopt cloud integration services to support digital transformation. That maturity means better tooling, better skills, and more integration partners familiar with this approach.

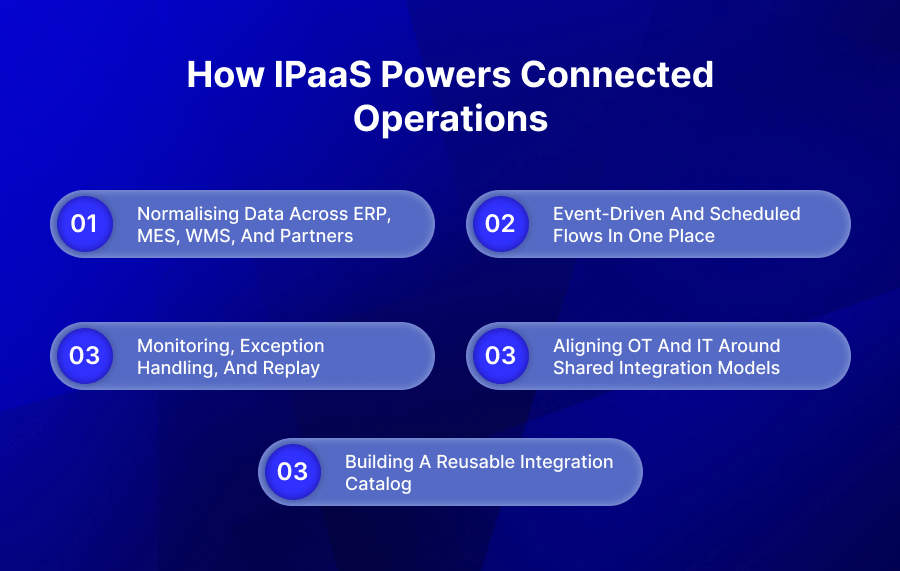

How iPaaS Powers Connected Operations

iPaaS changes integration from hidden point solutions into visible, governed flows. That shift matters on both the shop floor and in the boardroom.

Normalising Data Across ERP, MES, WMS, And Partners

iPaaS acts as a translation layer between core systems. Instead of mapping every pair individually, teams define canonical structures for major domains.

- Orders: One contract for all customer orders, regardless of entry channel.

- Inventory: One structure for stock, locations, and statuses, regardless of warehouse system.

- Production Events: Clear definitions for start, stop, scrap, and rework events across different machines or MES tools.

Once these contracts are set, new applications and partners map into them. Changing one system does not require rebuilding the entire network.

Event-Driven And Scheduled Flows In One Place

Different manufacturing domains need different tempos. iPaaS lets teams combine event-driven and scheduled flows inside one platform.

- Event-Driven Examples: Order intake, production confirmations, quality holds, shipping updates.

- Scheduled Examples: Nightly inventory snapshots, planning data extraction, cost-roll updates.

Teams can choose where they need near real-time updates and where regular batches are enough. As needs change, they adjust schedules and triggers centrally instead of editing scripts in multiple systems.

Monitoring, Exception Handling, And Replay

A modern iPaaS provides dashboards that show message volumes, freshness by domain, and error rates. Integration stops being a black box.

When a flow fails, operators see:

- The record that failed.

- The rule or condition that rejected it.

- The options available: fix in-source, override, or replay.

Replay features use idempotent behaviour, so resending a record does not create duplicates. That combination reduces recovery time and gives leaders confidence that integration issues will not silently damage performance.

Aligning OT And IT Around Shared Integration Models

Operations technology teams care about uptime, line performance, and safety. IT teams focus on data quality, security, and maintainability. Both groups depend on each other, yet they often work from different tools, vocabularies, and project rhythms.

iPaaS gives them a shared place to design and review integration flows. OT experts describe the events that matter on the line: production starts, stops, scrap reasons, and downtime categories. IT experts translate those events into stable data contracts, security policies, and routing rules that applications can trust.

Workshops shift from debating individual scripts to agreeing on domains and contracts. Teams review flows visually, decide where validation should happen, and set clear ownership for corrections when data fails checks. Over time, this becomes a common language.

The result is less friction between plants and central teams. Changes to machines, products, or partners enter a known process. Integration supports continuous improvement instead of becoming a blocker each time operations need to move.

Building A Reusable Integration Catalog

As factories adopt more flows, projects often repeat the same work with new labels. Teams rebuild similar mappings for orders, shipments, inventory adjustments, and production events because no shared library exists. That wastes time and hides knowledge in individual projects instead of lifting the whole organisation.

An iPaaS catalog solves this by treating integrations as reusable products. Each flow gains a clear name, a version, a short description, and a defined owner. Engineers document which systems it connects, which contracts it uses, and which policies apply. When a new plant or partner needs similar behaviour, teams start from a trusted template rather than improvising.

Over time, the catalog becomes a menu of approved patterns for common scenarios: adding a new supplier, onboarding a distributor, connecting a contract manufacturer, or exposing order status to a customer portal. Internal requests shift from “build this from scratch” to “adapt that existing flow”. That habit cuts delivery time, reduces defects, and makes integration skills easier to share across Singapore and regional sites.

Benefits for Singaporean Manufacturers

iPaaS benefits rarely arrive as one dramatic change. They show up in daily routines, then compound over quarters.

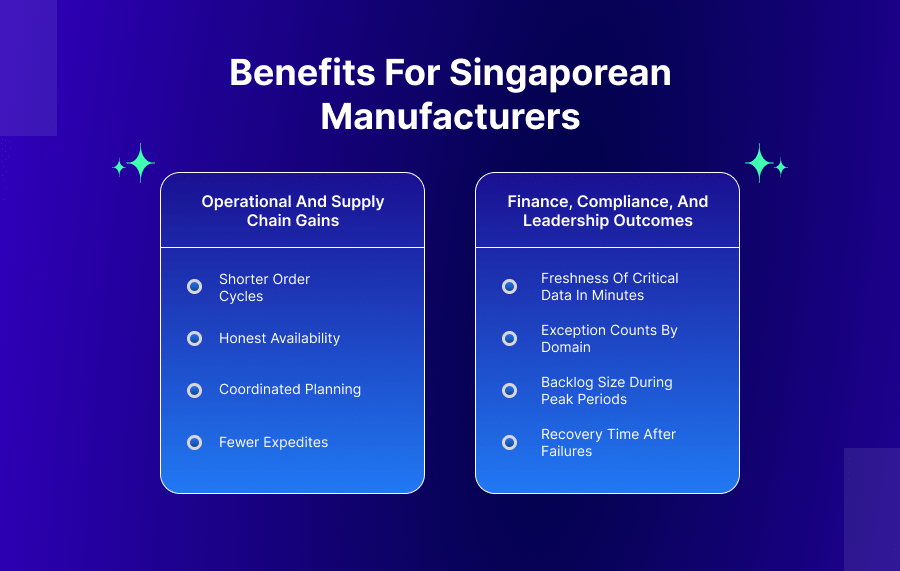

Operational And Supply Chain Gains

Connected systems reduce rework and delays along the order path. Teams spend less time reconciling and more time improving processes.

- Shorter Order Cycles: Orders flow from portal to ERP to production without repeated imports.

- Honest Availability: Inventory reflects receipts, reservations, and holds fast enough to avoid unpleasant surprises.

- Coordinated Planning: Demand, capacity, and material data line up across plants, suppliers, and customers.

- Fewer Expedites: Better visibility reduces last-minute freight upgrades and manual interventions.

In a region where logistics and labour are tightly managed, these gains protect margin and customer trust.

Finance, Compliance, And Leadership Outcomes

For finance, consistent integration means fewer unexplained differences between ERP reports, bank statements, and external platforms. Tax calculations, credits, and adjustments follow clear references instead of ad-hoc notes.

For compliance teams, integration events produce logs and evidence. This helps demonstrate that data is processed with appropriate safeguards under PDPA and internal policies.

Leadership gains a small set of integration metrics to track:

- Freshness of critical data in minutes.

- Exception counts by domain.

- Backlog size during peak periods.

- Recovery time after failures.

These numbers show whether integration keeps up with Singapore’s manufacturing ambitions or quietly holds them back.

Example Use Case

Orders arrive from several channels: direct B2B portal, distributors, and platform marketplaces. Each source has different formats and reference rules.

Staff manually consolidate these orders and enter them into ERP. Production planners export data into spreadsheets for capacity planning. Contract manufacturers receive updates through email attachments and one-off portal uploads.

Inventory systems update at different times. Customer service teams struggle to answer simple questions like “when will this order ship?” or “how many units remain in Singapore stock?”

Designing An iPaaS-Centred Architecture

The manufacturer introduces an iPaaS layer as the front door for all orders and the backbone for operational data.

- Order Intake: iPaaS accepts orders from portals, distributor feeds, and marketplaces, then standardises them into a common format.

- ERP And Plant Updates: Confirmed orders flow into ERP and then to plant systems for scheduling and material allocation.

- Contract Manufacturer Flows: Selected orders are routed to contract manufacturers through APIs or structured file exchanges, all using the same identifiers.

Inventory, production confirmations, and shipment events return through the same platform. iPaaS keeps online availability and partner dashboards aligned with actual movements.

After iPaaS: Measured Improvements

The company measures several changes over the following quarters:

- Fewer order-entry errors and disputes about quantities or promised dates.

- Reduced cycle time from order receipt to production start.

- More accurate available-to-promise views in sales tools.

- Lower manual effort in finance for reconciliations and credit notes.

When a problem appears, teams open the iPaaS console, inspect the relevant flow, and correct or replay records with clear context.

Why APPSeCONNECT Fits Singapore’s Smart Manufacturing Vision

APPSeCONNECT is an iPaaS platform focused on connecting business applications such as ERP, CRM, commerce, and supply chain systems through pre-built connectors and low-code tools.

For Singapore manufacturers, it offers a way to support Industry 4.0 and Smart Nation goals without rebuilding existing systems from scratch.

Hybrid Deployment For On-Premise Plants And Cloud Apps

Many manufacturers keep ERP, MES, and WMS inside secured environments while adopting cloud services for collaboration, analytics, and customer engagement.

APPSeCONNECT supports this model with a hybrid design. A local agent connects to internal systems, while the cloud portal hosts configuration, orchestration, and monitoring. Data that must stay within plant or data centre boundaries can be processed through the agent.

This combination helps manufacturers respect internal policies and local security expectations while still gaining the advantages of a managed integration platform.

Pre-Built Connectors And Visual ProcessFlows

APPSeCONNECT provides connectors and templates for widely used ERP, CRM, and commerce platforms. Manufacturers can start by adopting templates for order sync, inventory updates, pricing, and customer records.

The ProcessFlow designer presents integrations as visual flows. Each step appears as a block with clear inputs and outputs. Operations, IT, and finance teams can review and adjust mappings without digging into dense code.

Over time, companies can add plant-specific flows that handle production events, quality outcomes, or maintenance notifications. These patterns become reusable assets when new sites or partners join.

Governance, Monitoring, And Regional Experience

APPSeCONNECT includes monitoring dashboards, alerting, and controlled replay. Integration owners see which flows are healthy, where errors occur, and how long recovery takes.

Role-based access control enables separation between designers, operators, and auditors. That structure supports internal governance and aligns well with the process discipline encouraged by frameworks such as the Smart Industry Readiness Index.

Partners familiar with APPSeCONNECT operate across Asia, including work with manufacturers that manage cross-border supply chains and regional sales channels. This experience helps Singapore businesses move from pilots to durable integration programs.

Final Thoughts

Singapore’s manufacturers use advanced tech and follow strict rules while growing fast. Integration is the quiet base that keeps everything working.

By using iPaaS—especially APPSeCONNECT—manufacturers replace scattered, manual connections with a disciplined integration layer. It links plants, partners, and finance, which shortens cycles, cuts errors, and gives leaders trusted data for smart manufacturing plans.

Frequently Asked Questions

It is an integration platform that connects ERP, plant systems, suppliers, and channels using governed workflows instead of one-off scripts.

It provides reliable data flows between machines, MES, ERP, and analytics, which are essential for automation, traceability, and continuous improvement.

Yes, hybrid iPaaS deployments connect local systems through agents while orchestrating flows in the cloud for monitoring and governance.

No, mid-sized manufacturers often start with one or two domains, then extend coverage as benefits and requirements grow.

It centralises policies, logging, and access control for integration flows, helping teams demonstrate responsible handling of personal and sensitive data.

It connects leading ERP, CRM, and commerce platforms, then extends to other business and operational systems through configurable ProcessFlows.

Timelines depend on scope, but many teams deliver a targeted, domain-focused flow in a matter of weeks, not many months.

It standardises identifiers and reduces mismatches, feeding cleaner data into dashboards for orders, inventory, margins, and cash positions.

No, most changes rely on low-code configuration in the visual designer, with specialised development reserved for complex transformations.

Select one critical integration gap, map its current manual steps, and design a focused iPaaS flow that proves value clearly.